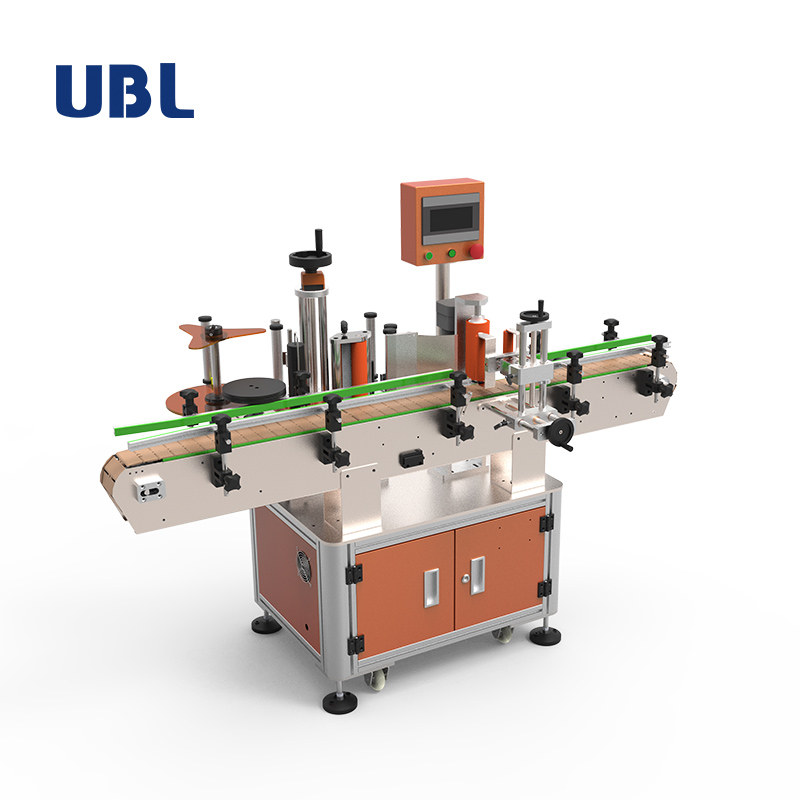

Positioning automatic round bottle labelingmachine

|

LABEL SIZE: |

15-160mm |

APPLICABE DIMENSIONS: |

Step:25-55pcs/min,Servo:30-65pcs/min |

|

POWER: |

220V/50HZ |

BUSINESS TYPE: |

Supplier, Factory, Manufacture |

|

MATERIAL: |

Stainless Steel |

ADVANTAGE: |

Engineers Available To Serive Machinery Oversea |

Basic Application

UBL-T-401 It can be applied to the labeling of circular objects such as cosmetics, food, medicine, disinfection of water and other industries.

Single-label and double-label sticking on bottle-shaped objects are possible with just one device. For double-label sticking, space between the two labels can be adjusted.Optional circumferential positioning detection device can be achieved in the circular surface of the designated location labeling.

Optional ribbon printer and inkjet printer, printing on the label in the production date and batch number of information, to achieve labeling - code integration

Technical Parameter

| Positioning automatic round bottle machine | |

| Type | UBL-T-401 |

| Label Quantity | One or two labels at a time |

| Accuracy | ±0.5mm |

| Speed | 25~55pcs/min |

| Label size | Length20~300mm;Width15~165mm |

| Product size(Vertical) | Diameter30~100mm;height:15~300mm |

| Label requirement | Roll label;Inner dia 76mm;Outside roll≦300mm |

| Machine size and weight | L1950mm*W1200mm*H1530mm; 200Kg |

| Packing size weight | L1910*W1120*L1670mm;about 350kg |

| Power | AC 220V ; 50/60HZ |

| Additional features |

|

| Configuration | PLC control;Have sensor;Have touch screen;Have conveyor belt;Have cylinder;Need air compressor |

| When the bottle labeling position is recessed, and need Positioning labeling .it is suitable to use this machine. | |

Our Services

In line with the principle of customer first, to provide customers with satisfactory after-sales service.

1, Pre - provide professional technical advice, to guide the reasonable selection of customers;

2, The use of labeling machines to provide training services, to guide customers to use and maintain the correct labeling machine;

3, To provide technical support services, to guide customers to solve the labeling machine related supporting services;

4, Equipment warranty for one year, after the warranty period, to provide maintenance services.

Characteristics of Function:

Optional ribbon code printer can print production date and batch number, and reduce the bottle packaging procedure to boost production efficiency.

Optional automatic turntable machine can be directly connected to the front end of the production line, feeding bottle into the labeling machine automaticlly

Optional hot-stamping coder or inkjet coder

Automatic feeding function (according to the product)

Automatic collecting (according to the product)

Additional labeling equipment

Circumferential labeling through positioning

Other functions (according to the customer’s requirements).

Technical parameters: The technical parameters of the standard model are shown as follows. Customization is available if there are any particular requirements of functions.

TAG: bottle labeling equipment, bottle label applicator machine