China Wholesale Bottle Labeller Suppliers - Large carton special labeling machine – UBL

China Wholesale Bottle Labeller Suppliers - Large carton special labeling machine – UBL Detail:

|

APPLICABLE: |

Box, Carton ,Plastic Bag Etc |

MACHINE SIZE: |

3500*1000*1400mm |

|

DRIVEN TYPE: |

Electric |

VOLTAGE: |

110v/220v |

|

USAGE: |

Adhesive Labeling Machine |

TYPE: |

Packaging Machine, Carton Labeling Machine |

Basic Application

UBL-T-305 This product specific to large cartons or large cardboard adhesive for development, With two label heads, Can put two same labels or different labels on front and back at the same time.

Can closed unused labeler head and put up single label.

Application carton width ranges: 500mm, 800mm, 950mm, 1200mm, Application bottom papaer width ranges: 160mm,300mm

Technical Parameter

| Large carton special labeling machine | |

| Type | UBL-T-305 |

| Label Quantity | One label at a time ( Or two labels before and after, do the same volume label. |

| Accuracy | ±1mm |

| Speed | 20~80pcs/min |

| Label size | Length6~250mm;Width20~160mm |

| Product size | Length40~800mm;Width40~800mm;Height2~100mm |

| Label requirement | Roll label;Inner dia 76mm;Outside roll≦250mm |

| Machine size and weight | L3000*W1250*H1400mm; 180Kg |

| Power | AC110V/ 220V ; 50/60HZ |

| Additional features | 1. Can add the ribbon coding machine 2. Can add transparent sensor 3. Can add inkjet printer or laser printer;barcode printer 4. Can add label heads |

| Configuration | PLC control;Have sensor;Have touch screen;Have conveyor belt |

Additional Features:

1. Can add the ribbon coding machine

2. Can add transparent sensor

3. Can add inkjet printer or laser printer; barcode printer

4. Can add label heads

Characteristics of Function:

1. Mechanical Operation:

The mechanical operation is usually operated in the condition of power, the relevant actions are firstly performed in a manual state in coordination with the adjustment.

1). Conveyor: Adjust the conveying mechanism to ensure the smooth delivery of the product to the labeling position, and send out smoothly. Place the products to be labeled on the left and right sides of the conveying mechanism for minor adjustment. For the specific operation method, please refer to the “Part 5 Adjustment” The same method is used for chapter, section, and delivery adjustment.

2). Labeling position adjustment: place the product to be labeled next to the peeling plate, adjust the labeling head up, down, front, back, left and right to ensure the label peeling position is aligned with the labeling position, adjust the guiding mechanism and ensure that the lable is pasted to the designated position of the product.

2. Electrical Operation

Turn on the power → Open the two emergency stop switches, start the labeling machine → Operation panel setting → start labeling.

TAG: flat surface label applicator, flat surface labeling machine

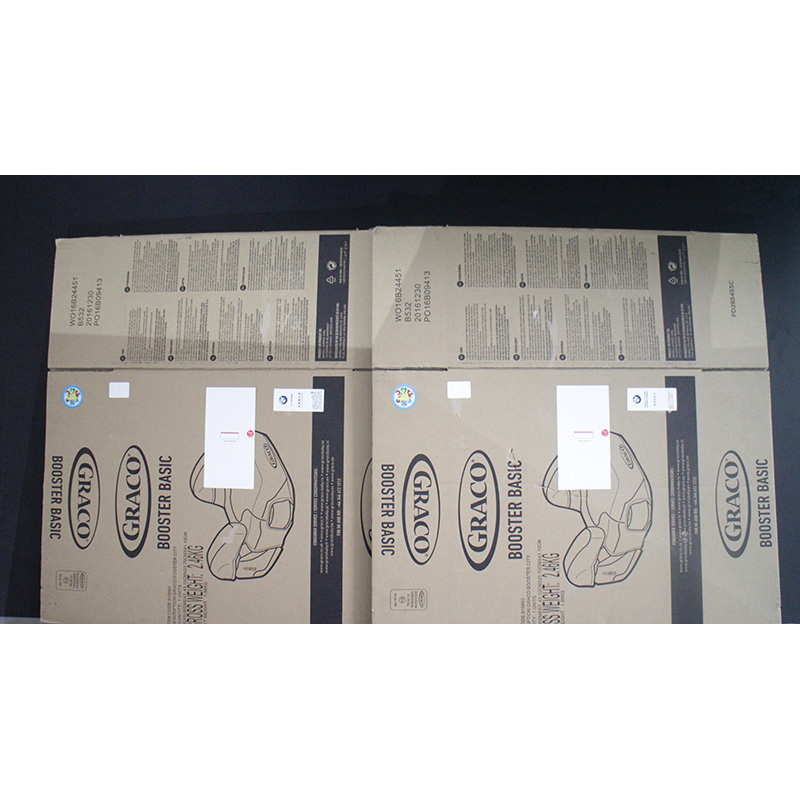

Product detail pictures:

Related Product Guide:

As a way to ideal meet up with client's desires, all of our operations are strictly performed in line with our motto "High Top quality, Competitive Cost, Fast Service" for China Wholesale Bottle Labeller Suppliers - Large carton special labeling machine – UBL , The product will supply to all over the world, such as: Benin, Houston, Amsterdam, We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and solutions and perfect service . We also warmly welcome customers to visit our company and purchase our products.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!