China Wholesale Automatic Labeling Factories - Card bag labeling machine – UBL

China Wholesale Automatic Labeling Factories - Card bag labeling machine – UBL Detail:

Characteristics of Function:

Stable card sorting: advanced sorting – reverse thumbwheel technology is used for card sorting; the sorting rate is much higher than common card sorting mechanisms;

Speedy card sorting and labeling: for monitoring code labeling on drug cases, production speed can reach 200 articles/minute or above;

Wide application scope: support labeling on all kinds of cards, paper sheets, and unfolded cartons;

Stable labeling accuracy: coping wheel is used for smoothing work piece, stable delivery, warping removing and accurate labeling; the sophisticated design of adjustment part, the label rounding and optional six positions for labeling make product change and label rounding simple and time-saving;

Intelligent control Automatic photoelectric tracking that avoids idle labeling while correcting and detecting labels automatically, so as to prevent mislabeling and label waste;

High stability PLC+ touch screen + Panasonic Panasonic needle + Germany Matsushita Electric eye Leuze label consisting of senior electric eye control system, support equipment 7 x 24 hour operation;

Automatic shutdown: labeled bottles numbering, power saving (the device will automatically change into standby mode if no labeling is detected within a given time), indication of labeled bottles and protection of parameter setting (hierarchical authority to parameter setting) bring much convenience to production and management

Technical Parameter

| Card /bag labeling machine | |

| Type | UBL-T-301 |

| Label Quantity | One label at a time |

| Accuracy | ±1mm |

| Speed | 40~150pcs/min |

| Label size | Length6~250mm;Width20~160mm |

| Product size(Vertical) | Length60~280mm;Width40~200mm;Height0.2~2mmother size can customized |

| Label requirement | Roll label;Inner dia 76mm;Outside roll≦250mm |

| Machine size and weight | L2200*W700*H1400mm; 180Kg |

| Power | AC 220V ; 50/60HZ |

| Additional features | 1.Can add the ribbon coding machine

2.Can add transparent sensor 3.Can add inkjet printer or laser printer barcode printer 4.Can add label heads |

| Configuration | PLC control;Have sensor;Have touch screen;Have conveyor belt;Have Feida.Have collect device. |

Optional functions

| Card /bag labeling machine | |

| Type | UBL-T-301 |

| Label Quantity | One label at a time |

| Accuracy | ±1mm |

| Speed | 40~150pcs/min |

| Label size | Length6~250mm;Width20~160mm |

| Product size(Vertical) | Length60~280mm;Width40~200mm;Height0.2~2mmother size can customized |

| Label requirement | Roll label;Inner dia 76mm;Outside roll≦250mm |

| Machine size and weight | L2200*W700*H1400mm; 180Kg |

| Power | AC 220V ; 50/60HZ |

| Additional features | 1.Can add the ribbon coding machine

2.Can add transparent sensor 3.Can add inkjet printer or laser printer barcode printer 4.Can add label heads |

| Configuration | PLC control;Have sensor;Have touch screen;Have conveyor belt;Have Feida.Have collect device. |

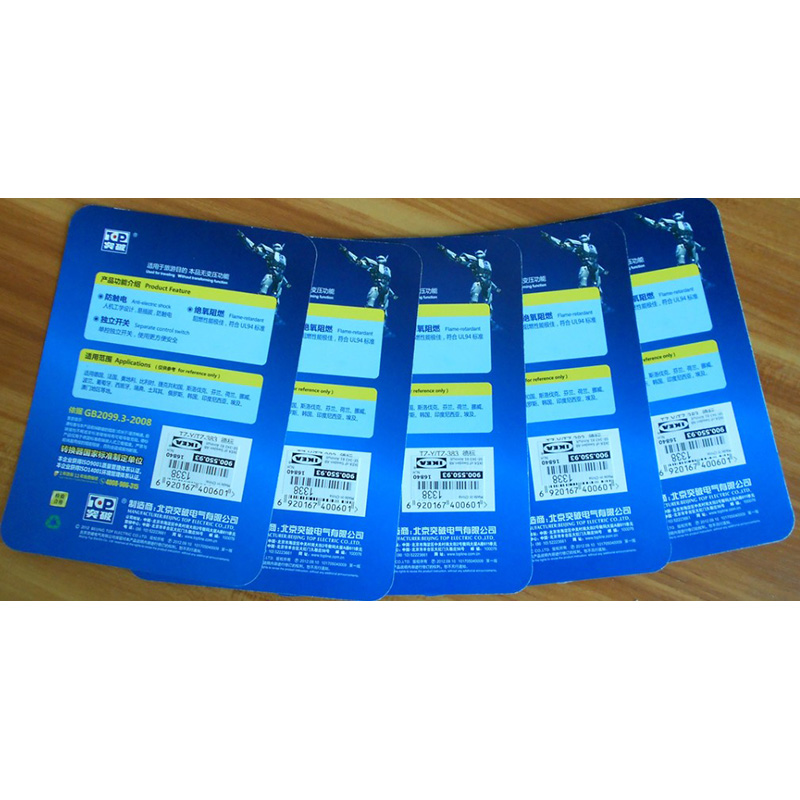

Product detail pictures:

Related Product Guide:

Our items are commonly identified and trusted by people and can fulfill repeatedly altering economic and social wants of China Wholesale Automatic Labeling Factories - Card bag labeling machine – UBL , The product will supply to all over the world, such as: Dominica, Stuttgart, Bolivia, Since always, we adhering to the "open and fair, share to get, the pursuit of excellence, and creation of value"values, adhere to the"integrity and efficient, trade-oriented, best way , best valve" business philosophy. Together with our all over the world have branches and partners to develop new business areas, maximum common values. We sincerely welcome and together we share in global resources, opening up new career together with the chapter.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.