Card bag labeling machine

Characteristics of Function:

Stable card sorting: advanced sorting - reverse thumbwheel technology is used for card sorting; the sorting rate is much higher than common card sorting mechanisms;

Speedy card sorting and labeling: for monitoring code labeling on drug cases, production speed can reach 200 articles/minute or above;

Wide application scope: support labeling on all kinds of cards, paper sheets, and unfolded cartons;

Stable labeling accuracy: coping wheel is used for smoothing work piece, stable delivery, warping removing and accurate labeling; the sophisticated design of adjustment part, the label rounding and optional six positions for labeling make product change and label rounding simple and time-saving;

Intelligent control Automatic photoelectric tracking that avoids idle labeling while correcting and detecting labels automatically, so as to prevent mislabeling and label waste;

High stability PLC+ touch screen + Panasonic Panasonic needle + Germany Matsushita Electric eye Leuze label consisting of senior electric eye control system, support equipment 7 x 24 hour operation;

Automatic shutdown: labeled bottles numbering, power saving (the device will automatically change into standby mode if no labeling is detected within a given time), indication of labeled bottles and protection of parameter setting (hierarchical authority to parameter setting) bring much convenience to production and management

Technical Parameter

| Card /bag labeling machine | |

| Type | UBL-T-301 |

| Label Quantity | One label at a time |

| Accuracy | ±1mm |

| Speed | 40~150pcs/min |

| Label size | Length6~250mm;Width20~160mm |

| Product size(Vertical) | Length60~280mm;Width40~200mm;Height0.2~2mmother size can customized |

| Label requirement | Roll label;Inner dia 76mm;Outside roll≦250mm |

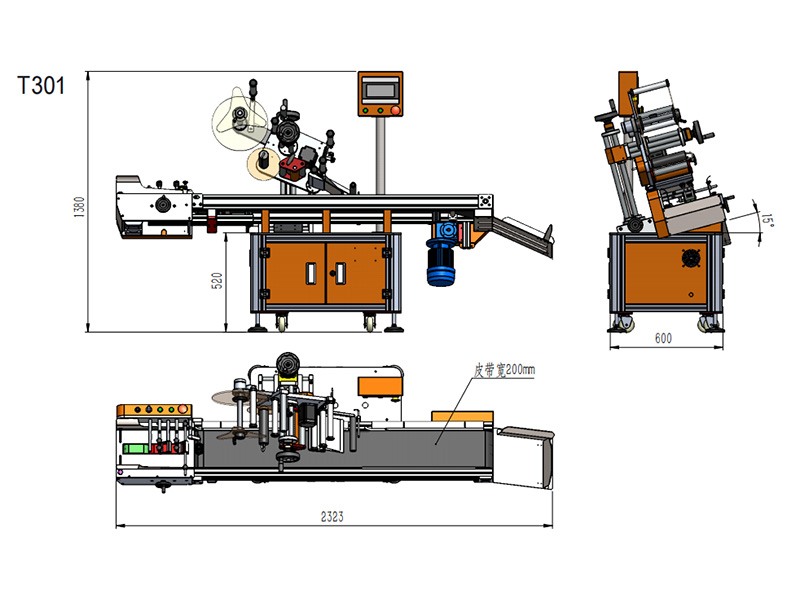

| Machine size and weight | L2200*W700*H1400mm; 180Kg |

| Power | AC 220V ; 50/60HZ |

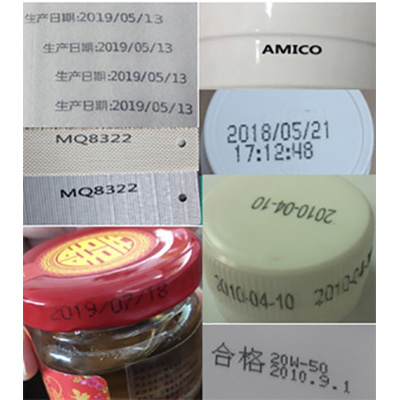

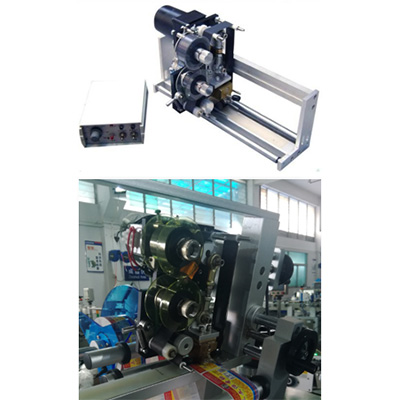

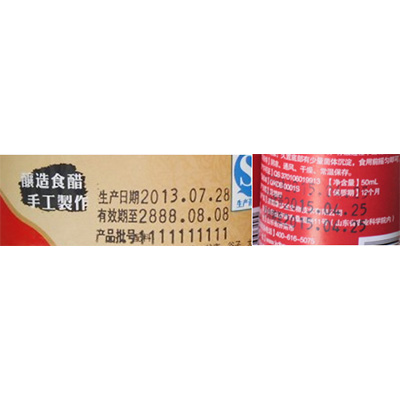

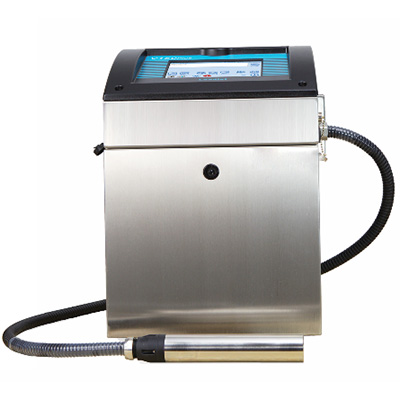

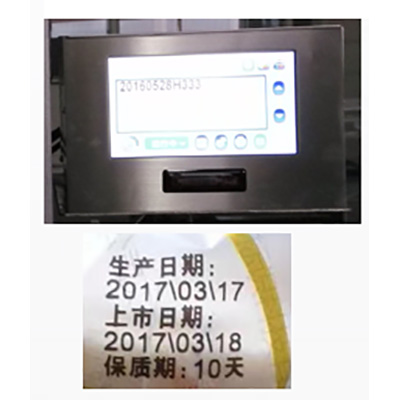

| Additional features | 1.Can add the ribbon coding machine

2.Can add transparent sensor 3.Can add inkjet printer or laser printer barcode printer 4.Can add label heads |

| Configuration | PLC control;Have sensor;Have touch screen;Have conveyor belt;Have Feida.Have collect device. |

Optional functions

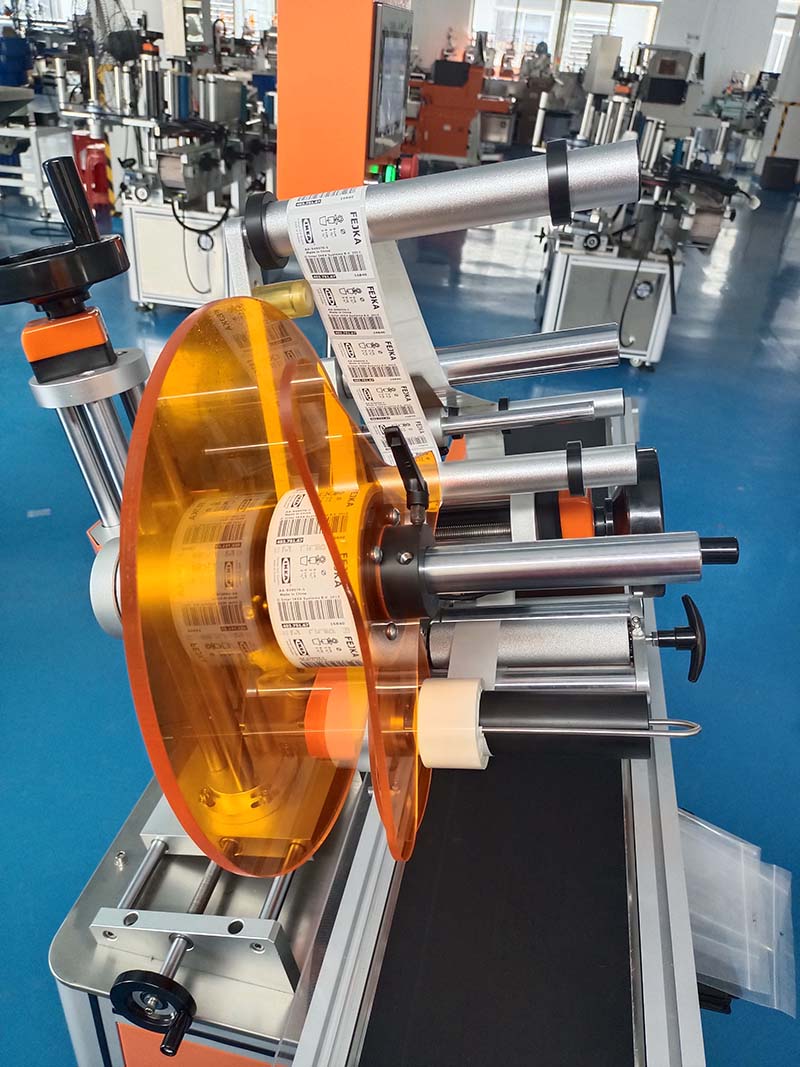

Machine size and details

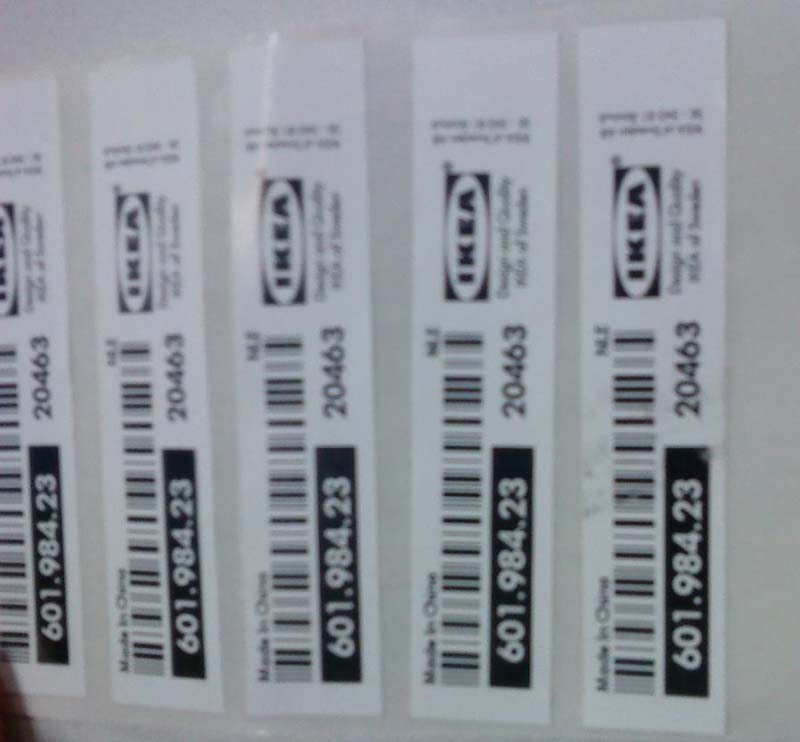

Label making diagram

Automatic card labeling machine label making reference:

1. The interval between labels is 2~4mm;

2. The label is 2mm away from the edge of the base paper;

3. The label backing paper is made of Gracine material (to avoid cutting the backing paper);

4. The inner diameter of the core is 76mm, and the outer diameter is less than 250mm;

5. Label to the right;

6. Single row of labels.

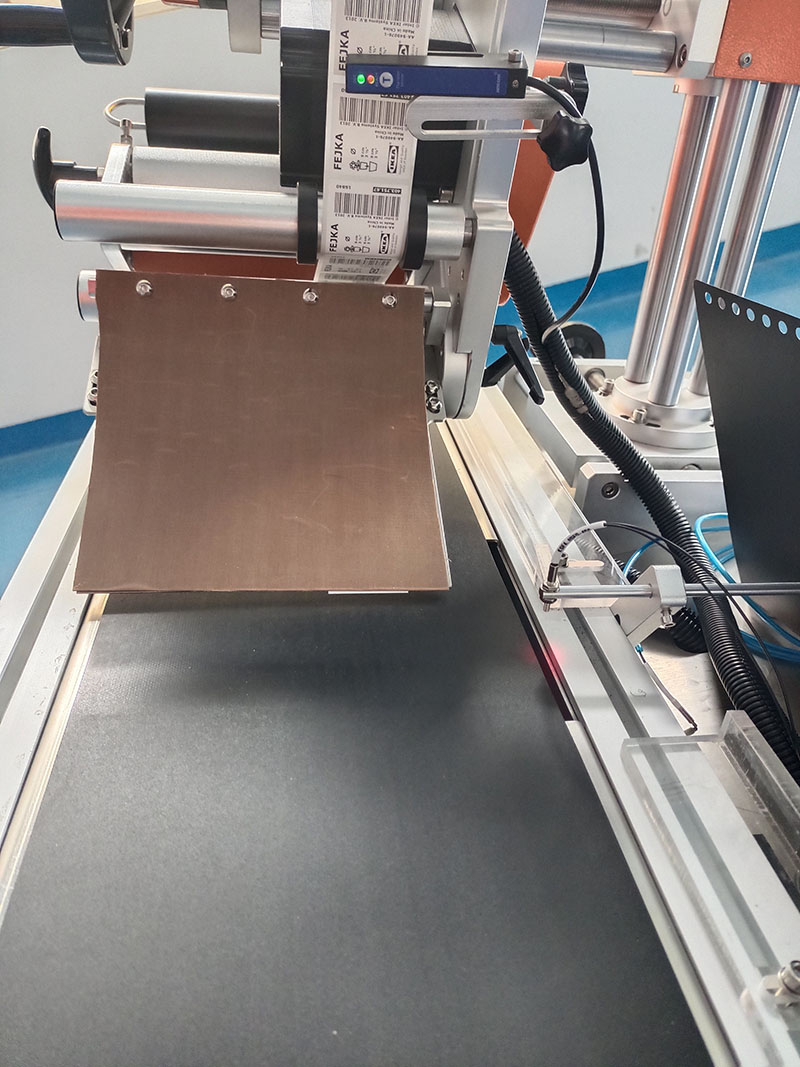

Customer usage scenario diagram

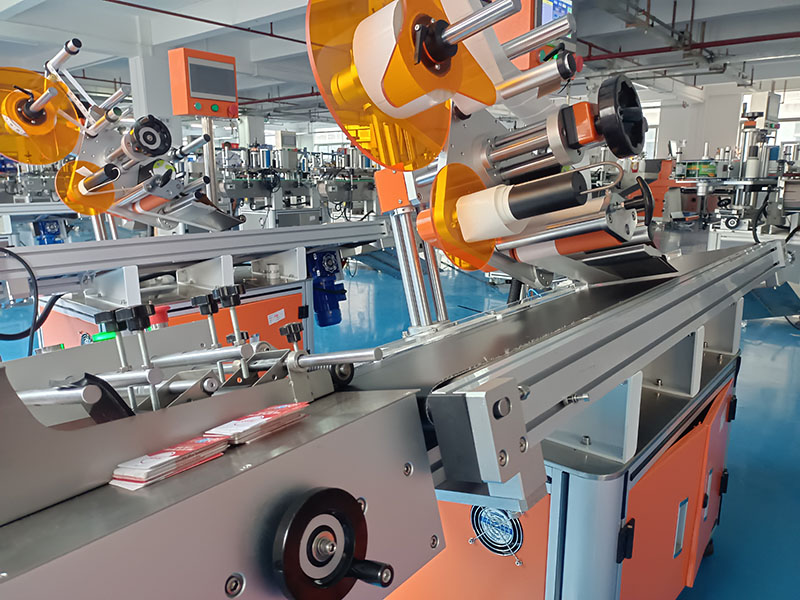

Work shop

Packing and shipping

TAG: flat surface label applicator, flat surface labeling machine